Smart Integrated Sensors Solutions

About SensIQ

SensIQ is a Phoenix, Arizona based company developing integrated sensor solutions enabling active AI on the Edge, with diverse applications in consumer, industrial, wearables, robotics, medical, and automotive markets.

SensIQ is led by an experienced team with over 200 years of experience with a proven record in innovation, design, development, and manufacturing of semiconductor products.

Our MIMS Technology

SensIQ has a patent-protected technology called MIMS (Monolithically Integrated Multi-Sensors) to integrate multiple diverse physical sensors on the same silicon substrate.

The MIMS technology provides the benefits of small size, low power consumption, lower cost, increased functionality, and better reliability.

The MIMS technology establishes a standard platform for the design and manufacturing of a wide variety of sensors, thus reducing the cycle time for new product design and introduction.

Our Business

The MIMS platform using inputs from multiple data streams of distributed sensors nodes is combined with AI processors in a system level integration scheme to enable real-time action-driven intelligence solutions, with unparalleled improvements in efficiency, productivity, performance, and security.

The MIMS technology enables novel solutions in industrial, automotive, consumer, wearables, robotics, medical, and Internet of Things applications.

MIMS Platform

The MIMS platform enables the co-design and co-fabrication of multiple, diverse sensors using a CMOS compatible process that uses standard materials, processes and equipment.

The MIMS technology uses a single fabrication process, a single ASIC (Application Specific Integrated Circuit), and a single assembly process in a single package.

This technology has already been proven with five sensors in a 3mm X 3mm chip.

Sensor Technology Evolution

Monolithic Fabrication Platform

The MIMS platform advances the integration roadmap from discrete packaged sensors integrated in a PCB (Printed Circuit Board) to multiple, different sensors integrated on the same chip using a common fabrication process in the front-end and a common assembly process in the back-end.

This sensor integration evolution results in increased functionality, performance, reliability and density with reduced cost and power consumption.

Monolithic Fabrication Platform

Monolithic Fabrication Platform

The MIMS platform enables the monolithic integration of multiple diverse sensors using standard MEMS process modules. The platform allows the design and fabrication of sensors that may be sealed from the environment at various levels of pressure and vacuum or be open to the ambient.

The monolithic integration is suitable to the development of a library of sensors that may be designed and fabricated with a common fabrication process flow using a PDK.

Wearables With Novel Form Factors

Wearables With Novel Form Factors

Wearables With Novel Form Factors

Combined with a high level of system integration, the MIMS platform enables the design of wearables with unique form factors.

Wearables in the form of a wrist band, pendant, chest strip, patch and sticker can be manufactured to provide multiple choices to the users.

Robotics and Automation

Wearables With Novel Form Factors

Wearables With Novel Form Factors

The MIMS platform allows the design of sensors and solutions that are very suitable for robotics and automation.

Many robotic applications need multiple, diverse sensors that respond to different input parameters while maintaining high sensitivity in a small, flexible form factor.

The small size and additional functionality of MIMS sensors are uniquely suited to support automation needed in factories, homes, buildings and equipment.

Airborne Platforms

Wearables With Novel Form Factors

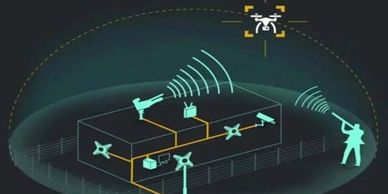

Airborne Platforms

The MIMS platform is very suitable for applications that are sensitive to weight, size, power consumption, performance and reliability. This is particularly true for drones that use inertial sensors such as accelerometers, gyroscopes, and magnetic sensors, and functional payloads.

Payloads may include sensors for environmental or situational monitoring. Furthermore, cost effective sensor redundancy and resiliency can be enabled with our MIMS technology.

Cybersecurity

Cybersecurity

Airborne Platforms

Monolithically integrated multiple sensor arrays produced with SensIQ’s MIMS technology are combined with SensIQ’s partner HES (High Entropy Security) patented Challenge-Response Pair (CRP) method to generate "zero-knowledge" and “zero trust” user Multi Factor Authentication (MFA). This enables development and manufacturing of cybersecurity devices with standardized Post Quantum Cryptography (PQC).

Crypto Wallets are a key target product area enabled by our combined hardware / software technologies.

Resiliency

Cybersecurity

Anti-Jamming

Sensor redundancy uses multiple sensors to eliminate single points of failure.

Sensor resiliency goes further by merging enhancements in hardware, software, and operational procedures to provide a broader ability to recover from failures and disruptions such as those caused by hacking.

Resiliency is achieved by combining the MIMS sensor technology and the cybersecurity software capabilities of our partner HES to provide real-time fingerprinting of arrays of sensors, detection of failures and fault injection, and real-time correction schemes.

Anti-Jamming

Cybersecurity

Anti-Jamming

Our hardware/software cryptography solutions enhance anti-jamming techniques.

Cryptographic Binding: the Challenge-Response protocol where the MFA response assures that the MFA token is valid only for that session and prevents MITM (Man-In-The-Middle) from injecting or replaying codes.

Out Of Band Verification: The MFA protocol includes sensor-based transaction details to assure authentication within a valid range of expected user/ambient parameters. This helps to identify anomalies as a result of suspicious fraudulent attempts.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.